|

Fachbereich: Specials

Erstveröffentlichung: 13.02.2015 Ausgedruckt am: 30.07.2017 |

Shale oil from oil shale

Is it possible, that small northern country Estonia, who imported almost all of it´s oil, will be great oil exporter in the near future? It is possible, sayd Eesti Energia, who has built two oil shale factories, what will produce oil from oil shale. And it became more efficient and environmental frendly than last decades.

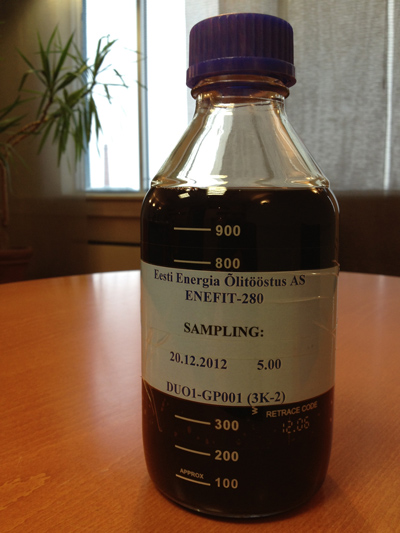

Enefit280 is the latest factory of Eesti Energia to produce oil of North-Eastaern oil shale resources, what are generally used for electric energy producing. But synthetic oil is much more beneficial. And there is unique technology for it - called Enefit – what is worked out by Eesti Energia scientists and engineers. Enefit280 got stability and started to produce oil last spring. For a long time the factory did not work according to plans because of some setbacks – unique technology was not working as expected and there were many problems with oil producing in the beginning. But for completely new technology it is normal. 35 MW electricitiy as by-productEnefit280 factory is producing oil from 260 tons of oil shale per hour now, what is the projected amount of the factory. The new generation of the plant will be the first in the world to produce oil combined with electricity production, which gives until 35 MW of electricity as by-product. Former Eesti Energia CEO Sandor Liive (meanwhile the company got a new CEO, Hando Sutter) is convinced, that it is not a technical question, when the new oil factory will be starting to work or not. „The factory actually works. That´s a fact. Our oil industry engineers can be proud of development works done, and the biggest oil shale factory producing oil is getting a top output volume now. We can say that Eesti Energia has developed oil producing technology of 21st century and this is the world record for now.“

Enefit280 is much more effective comparing to first generation plant Enefit140 because the new technology combines the oil production and the circulating fluidised bed incinerator. And this technology is, by the way, much more environment friendly than previous. Produced ashes are clean and re-usable. CO2 waste emits 40% less and oil yield is much bigger. Produced oil is much more improved, too. Great progress has been madeLet´s compare new oli producing factory Enefit280 with previous Enefit140, which stays right next to new factory in Nort-East Estonia, where Estonian oil shale mining is laid. Enefit140 processes 140 tons/hour of oil shale, but Enefit280 280 tons/hour. Energetic efficiency of Enefit140 is 71%, but Enefit280 – ca 90%. Enefit140 does not produce any electricity, Enefit280 is producing 20-35 MW. Enefit140 is not producing any steam, but Enefit280 is producing 90 tons/h of steam, what can be used for electricity production and heating.

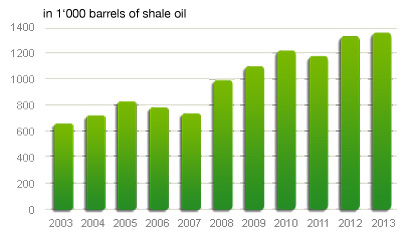

Enefit280 oil plant will produce about 2 million barrels of oil and 75 million cubic meters of gas yearly. 35 MW electric steam turbine produces electricity from residual heat. About 25 MW electric energy is the normal output of this plant. This is enough to meet all factory needs and to sell to public electric grid. The new plant will consume 2.26 million tons of oil shale per year and will produce 1.9 million barrels of shale oil and additionally 75 million m³ of hydrogen rich retort gas, plus 280 GWh of electricity per year. Long experiences in EstoniaEnefit280 produces shale oil from december 2012, but some problems prevented the ramp-up to full production. Nevertheless, for a – worldwide – completely new technology several years of practice before full-volume production is quite normal. For future, the technology of producing oil from oil shale is very promising, because oil shale resources are much bigger than natural crude oil resources. If technology develops, it becames much cheaper to produce synthetic oil from oil shale. Oil produced from oil shale is essentially synthetic crude oil and is made by heating oil shale, which has been done in Estonia for almost 100 years with technology that has been constantly developed. During the very low oil prices, Estonian oil producing have hard times to sell oil outside, but for a long period, it may be useful again to produce oil from oil shale. In the future, maybe even in the near future syntethic crude oil from oil shale may be cheaper than natural crude oil. It is very competitive as ship fuel in arctic conditions because shale oil is behaving better at very low temperatures than usual marine fuel. Export of the technology to USA and JordanIn addition to domestic production, Eesti Energia is developing oil shale projects in Jordan and in the USA, where company owns considerable oil shale reserves, and these projects are at the initial stage of development. There are still some minor problems with different types of oil shales, because Jordan and Utah oil shale needs a customized technology to produce more effeciently. But Eesti Energia aims to establish shale oil production facilities in these countries as well using the Enefit technology adapted to local oil shale. In the early 14th century, the first use of shale oil started in Switzerland and Austria. In 1915, an oil shale industry was established in Switzerland. So, it is possible for Switzerland to start oil producing, too, using the new shale oil technology. Comparing it with shale gas technique for extracting gas known as hydraulic fracturing or fracking, the shale oil technology is much more environment friendly. But of cource, all kind of mining is a risk to environment and must be considered very carefully. What is technology exactly?Enefit Technology is a unique combination of processing units, each of them serving special purposes such as drying and pyrolysis of oil shale, combustion of semi-coke, as well as the dedusting and cleaning of vapors and gases. How it´s exactly done, is business secret. And there are numerous patents for the key elements of Enefit Technology. Enefit's modular design is essential to the allowance of easy maintenance, process optimization and streamlined adaptability to the individual characteristics of different oil shale deposits. Eesti Energia have co-operation with company Outotec. Enefit Outotec Technology is a joint venture to develop and supply Enefit with plant engineering and experience in metals and mineral processing. Eesti Energia plans to be one of the biggest shale oil producers in the world. It almost is, because Estonia is the second largest shale oil producer in the world – after China.

13.02.2015 | Autor

Kaido Einama

|

o-mag.ch - Fachinformationen ausschlißlich online